Mass Production Tooling

We specialize in the production of high quality, mass production tooling and rapid molds. With a wide range of technologies at our disposal, we are the perfect one stop shop for all your prototyping needs. We offer low volume production from just 3 to 15 days!

Once you are ready to start your next project, contact our team to get a free quote.

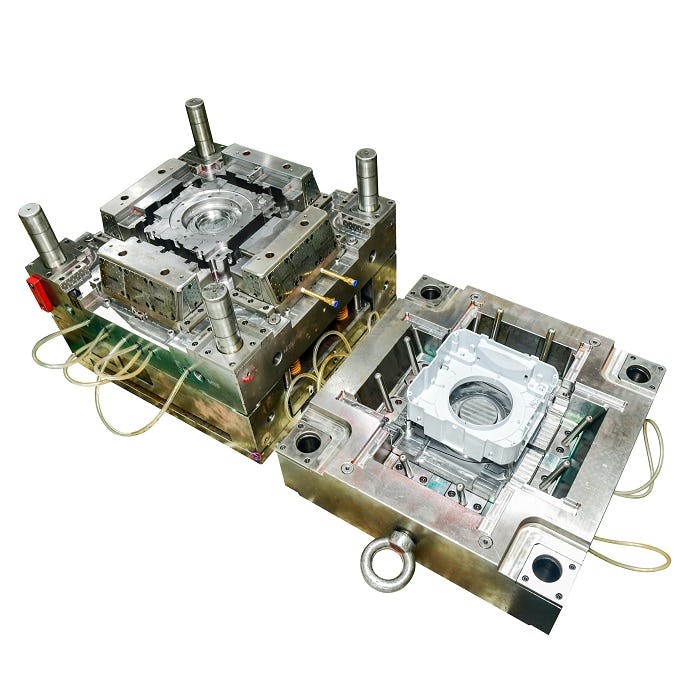

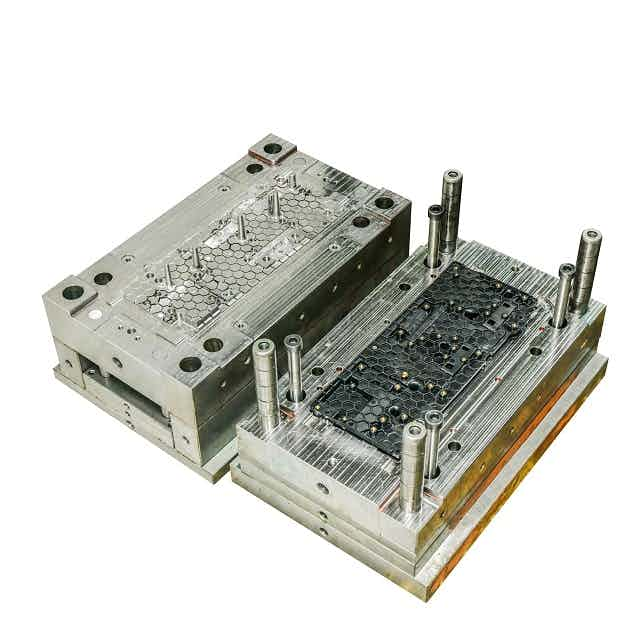

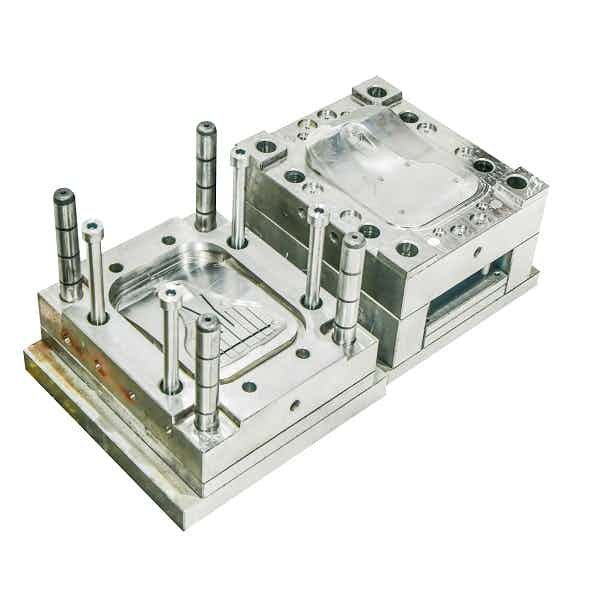

Here are two examples of our mass production tooling molds:

So What Is Mass Production Tooling?

Mass production tooling or mass production tools, involves the process of creating a large quantity of a product. The term “tooling”, infers using some kind of mold or tool which creates the product. Here at Shineyuu, this involves a metal mold which would create the product. The other piece of the term is “mass production”, which involves making large quantities of the same product over and over again. This in turn means that we can create large amounts of a product with our specifically crafted molds and materials using efficient methods.

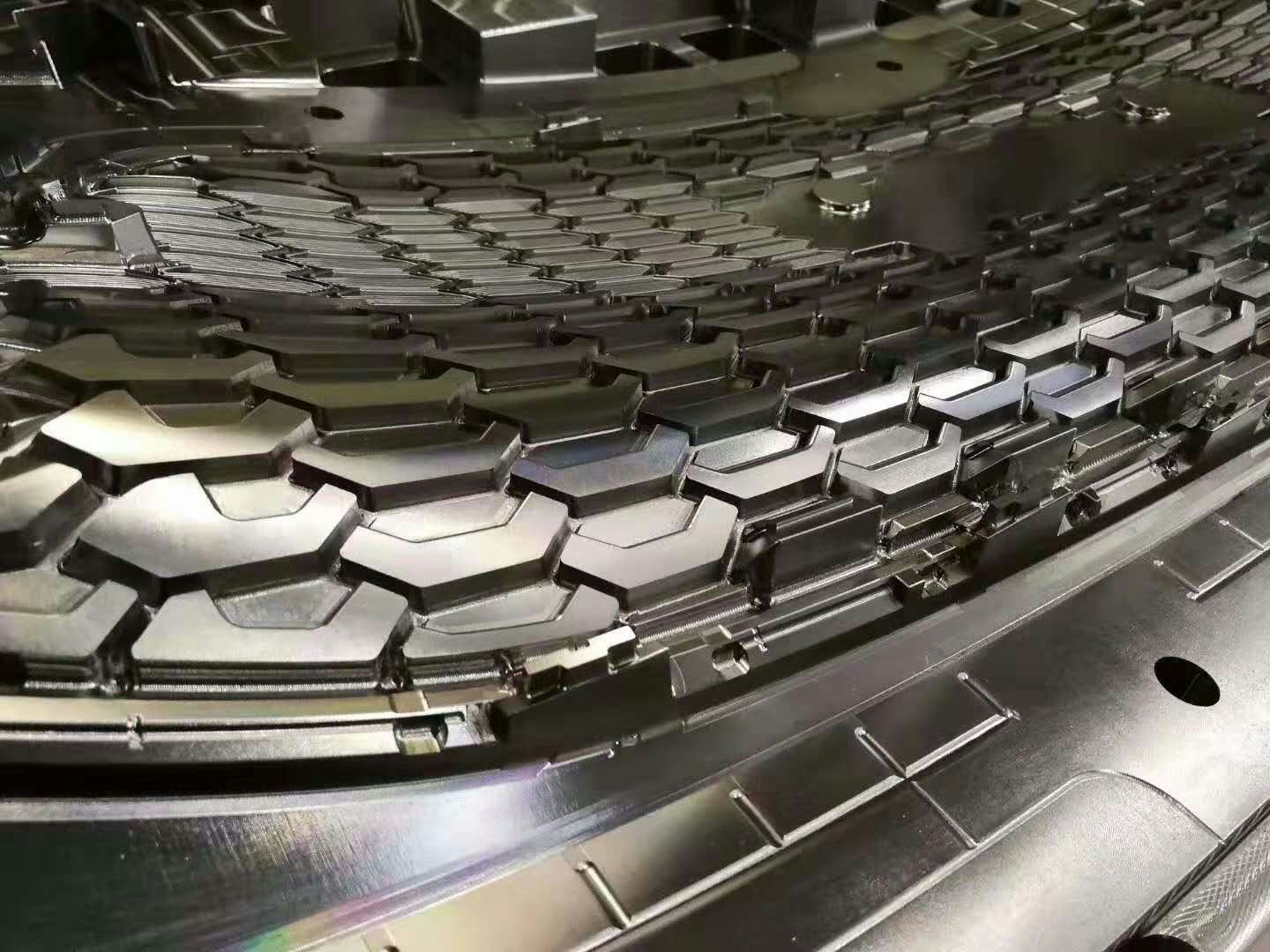

Here you can see a pretty mold design made right here at Shineyuu:

How Does Mass Production Tooling Work?

So how does mass production tooling work, exactly? Mass production tooling consists of transforming CAD models into a physical tool or mold using mass production methods, like that of injection moulding. The injection moulding process is comprised of three main components: the plastic injection molding machine, raw plastic and the machined mould. The plastic is then melted into the injection moulding machine and then injected into the mold where it cools and solidifies into its final part. Once the piece has finished cooling it is removed and completed.

Find out more about it on our rapid tooling page!

Below on the left you will see parts being packaged and ready for shipping!

On the right Shineyuu employees stack some plastic parts that have been created.

In the center you can see our mold team testing one of the mold pieces before production.

What Are The Advantanges Of Mass Production Tooling?

Mass production tooling provides a wide array of advantages, including:

- Cost: Mass production cuts the costs of workers on the factory line. Instead of having to pay dozens of workers for completing hand-given tasks, these manufacturers can now use assembly lines or machines at a lower cost without losing profits.

- Speed: Using machines and automation significantly impacts speed. Instead of workers needing to run around in order to gather parts, everything runs along an orderly and processed assembly line, cutting times to a fraction of what it would be otherwise.

- Uniformity: Mass production tooling is there to ensure that all parts look the same. With less room for error, both the manufacturer and the customer know what to expect. This in turn leads to a higher standard of quality. A product made by hand however, runs the risk of having errors, or that no two parts may necessarily look the same.

- Less errors: With all that in mind, mass production machines are less likely to make mistakes over human workers when undergoing production. A machine doesn’t get distracted or have a bad day, it simply works as its supposed to and the quality is maintained and uniform throughout.

Below you can see parts prepared and packaged by our team, ready for shipping on the left. On the right is a low-volume quantity of phone covers produced by us.

Production Molds

Below you can see a selection of production molds that we have used previously.

Injection Molded Parts

Here you will see some samples of our injection moulded parts created in production.

Tooling Facility

Take a look at some of our tools.

How Shineyuu Does Mass Production Tooling

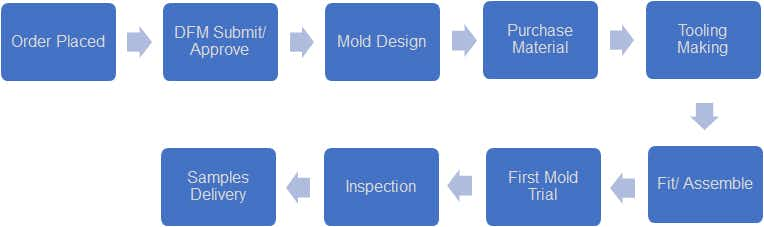

The below image shows the process of how we bring your design idea to reality.

Here at Shineyuu, we happily provide superior mass production tooling services at extremely competitive prices. We utilize steel molding tooling techniques, which is utilized as part of the molding process to create multiple copies of your parts. Our services include rapid tooling and mass production tooling. For more information or to get a quote from us, please contact us today!

If you have any questions, check out our FAQ section here.

Please provide 3D files and give us as much information as you can.

- Application Data (mold material, finish, etc.)

- Volume of parts required from the tool.

- Tolerances of the component.

- Life of the project.

We can then complete our specification sheet and evaluate the costs more exactly.

Check out our rapid prototyping tooling and manufacturing pdf here!