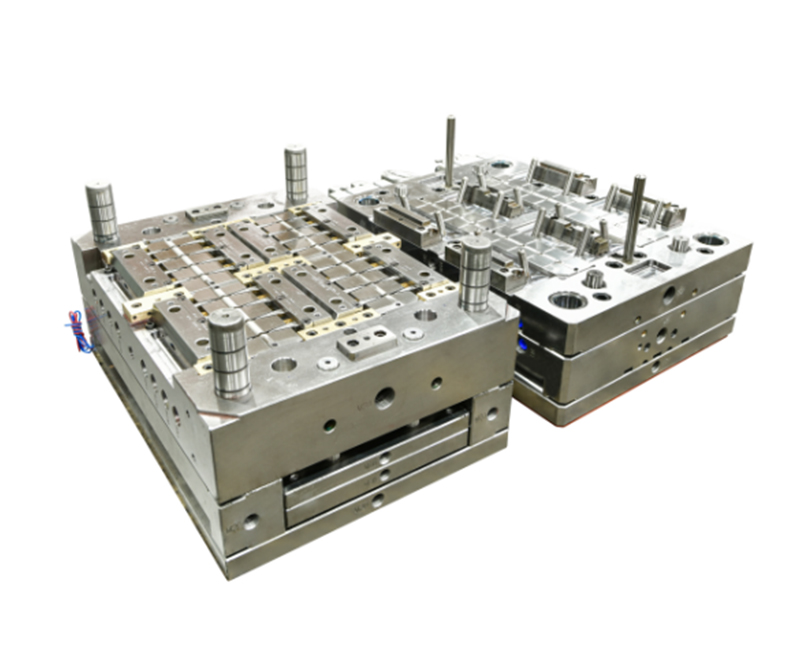

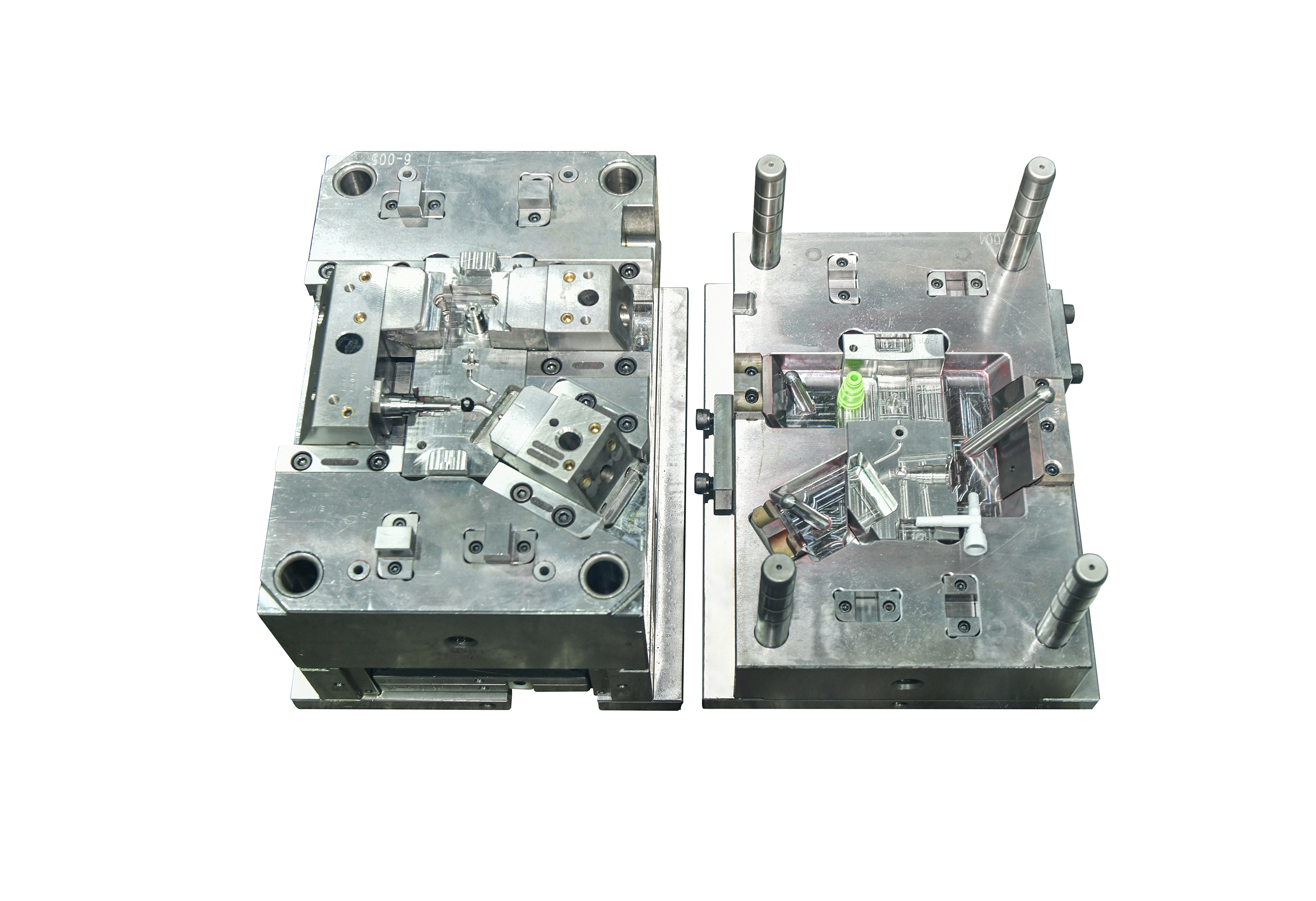

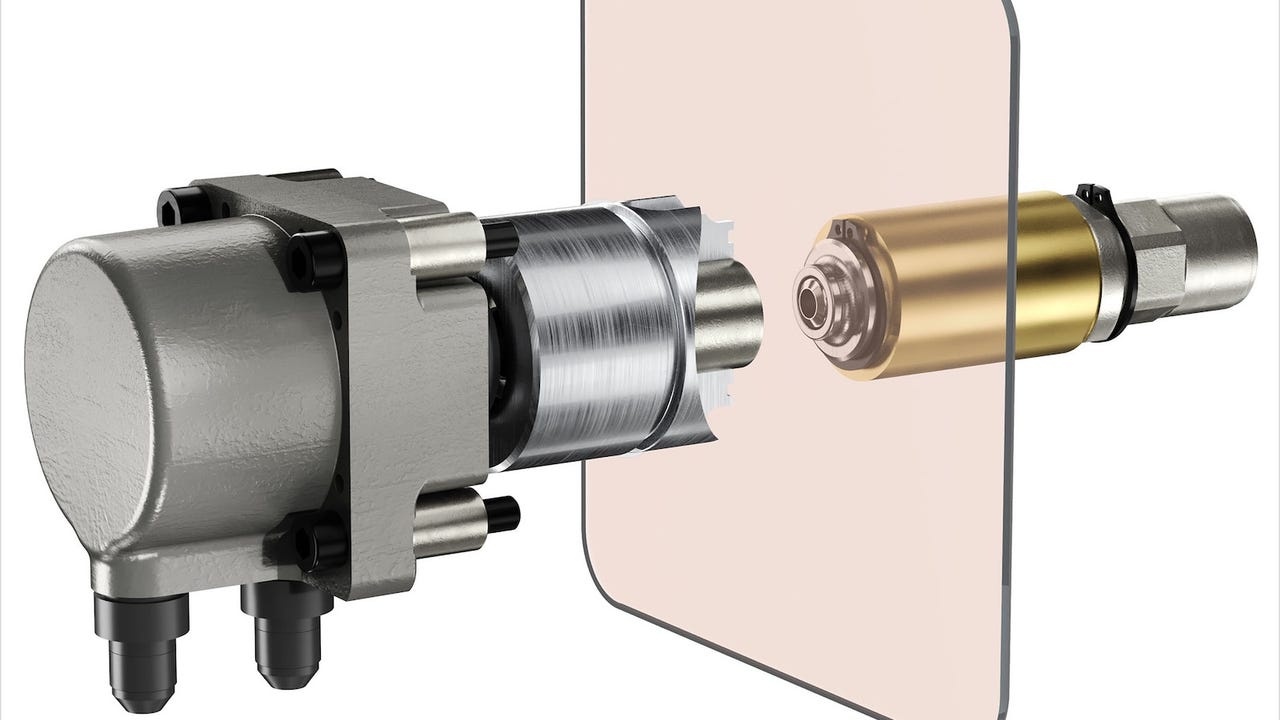

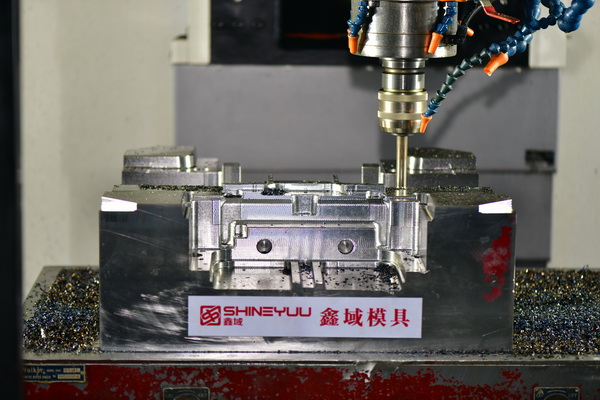

Shineyuu-mold Plastics is an ISO 9001:2015 IATF 16949 certified company that offers end-to-end molded plastic product solutions for a diverse set of industries, including automotive, medical and electronic. Our expert team has the knowledge and skills to meet all of your plastic injection molding needs.