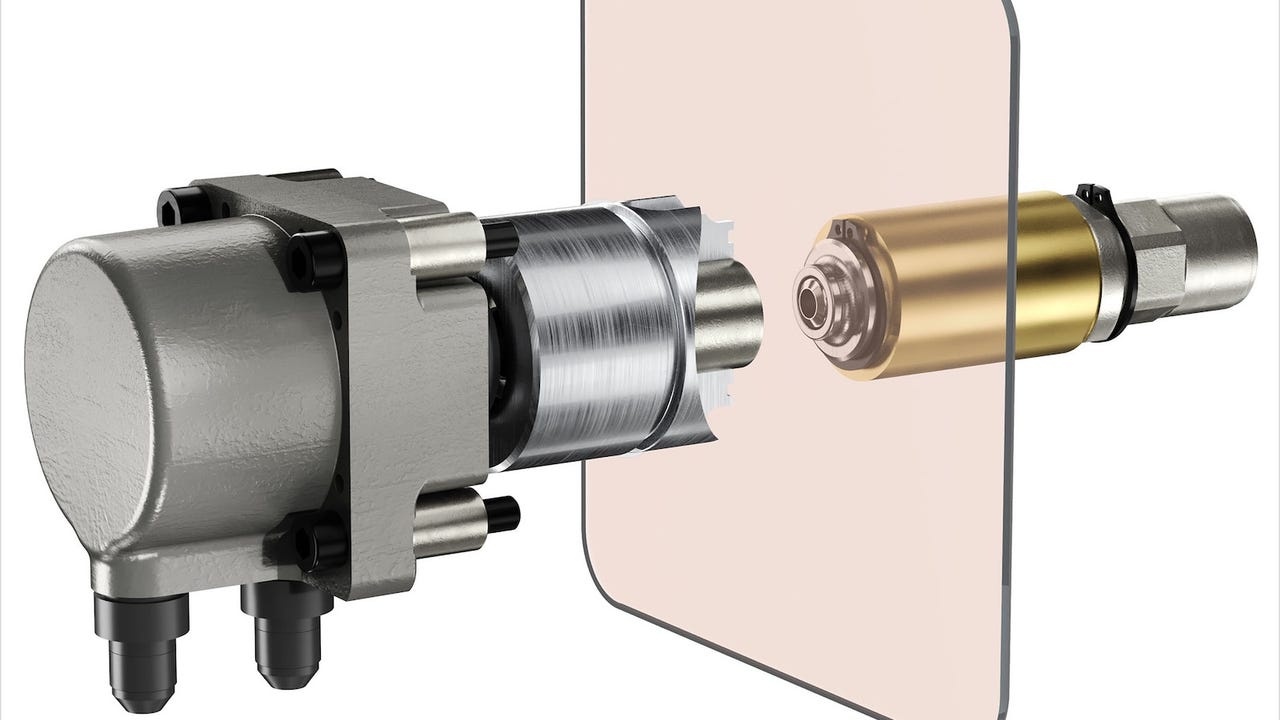

Valve gating systems have experienced consistent growth in hot runner mold applications across industries such as automotive, electronics, and medical devices. These systems deliver notable manufacturing advantages, including precise plastic flow control to improve part quality, reduced cycle times, and elimination of gate issues such as stringing and drooling. A key innovation, sequential valve gating (SVG) technology allows for programmed timing sequences that open and close valve gates, enabling better control over cavity fill patterns and effectively addressing weld or knit line surface problems.

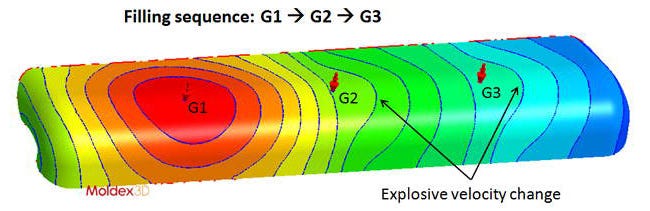

However, implementing SVG introduces challenges. As the filling process extends, pressure within the hot runner system rises: When a previously closed valve pin opens, a high-velocity surge of pressurized plastic enters the cavity, risking surface defects such as flow marks and uneven gloss.

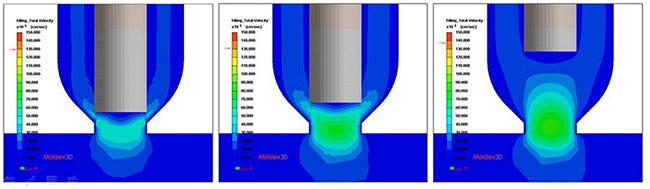

Real-time pin movement. Image courtesy of Moldex3D.

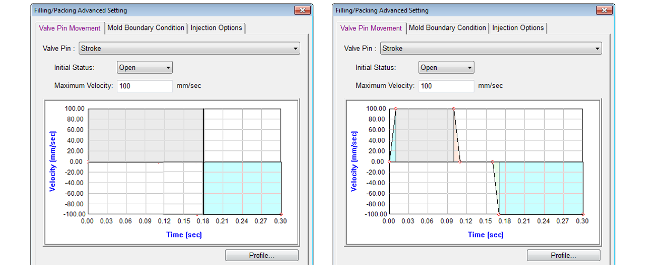

Advanced meshing tools enable accurate representation of complex valve gating systems, including hot runner components and valve pins, capturing geometric nuances for more reliable results. Simulation also offers flexible parameter controls — such as gating conditions, pin speeds, and multi-section movement profiles — giving engineers a comprehensive understanding of how different variables influence part quality and cycle efficiency.

The role of simulation. Image courtesy of Moldex3D.

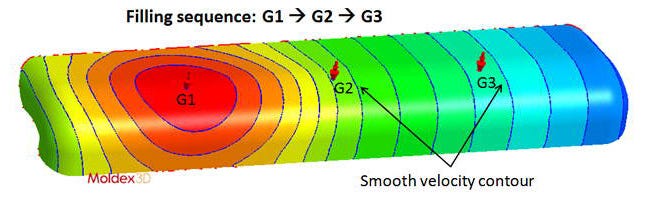

Moreover, simulation plays a pivotal role in overcoming these challenges. By modeling valve pin movement, engineers can analyze how precise control of pin motion and speed profiles impact flow dynamics. This insight enables optimization of timing and velocity settings, reducing the occurrence of flow marks and improving surface finish. Visual simulations of velocity fields help identify regions where pressure or flow fluctuations may cause defects, guiding design adjustments before physical production.

Constant pin movement (left) versus profiled pin movement. Image courtesy of Moldex3D.

Illustration of simulation-driven constant pin movement versus optimized profiled valve pin movement for gating design and superior part quality. Image courtesy of Moldex3D.

By utilizing detailed flow analysis and movement simulation, manufacturers can anticipate potential molding issues, refine gating strategies, and achieve optimal fill patterns. This proactive approach helps maximize the benefits of advanced valve gating systems, leading to improved product consistency, reduced waste, and shortened development cycles in modern plastic injection molding.

The Moldex3D R&D Team contributed to this article.