A new mold concept developed by Zahoransky is engineered to accelerate the mass production of housings for insulin pens and auto injectors in a space- and energy-efficient manner.

The Z.Sonic turn reportedly enables up to a 30% reduction in cycle time, increasing output by approximately one-third, and delivers manufacturing cost savings of around 20% per part compared with conventional mold technologies for this application, according to Zahoransky. The company claims that ROI calculations show that the investment can be amortized after approximately nine months.

GLP-1 drug market projected to grow at compound annual rate of 17%

The system was developed in response to growing demand for injectors, primarily because of the rapidly growing market for GLP-1 drugs to treat Type 2 diabetes and chronic weight management. The global GLP-1 market was valued at about $52 billion in 2024 and is expected to rise at a 17% compound annual growth rate, reaching a value of $187 billion by 2032, according to financial and investment advice firm The Motley Fool.

World debut at K 2025

Introduced at K 2025 in Düsseldorf, Germany, last month, the Z.Sonic turn was demoed as part of a production line with the Elion Med injection molding machine from Netstal and hot halves with servo-electric needle valve control from Ewikon.

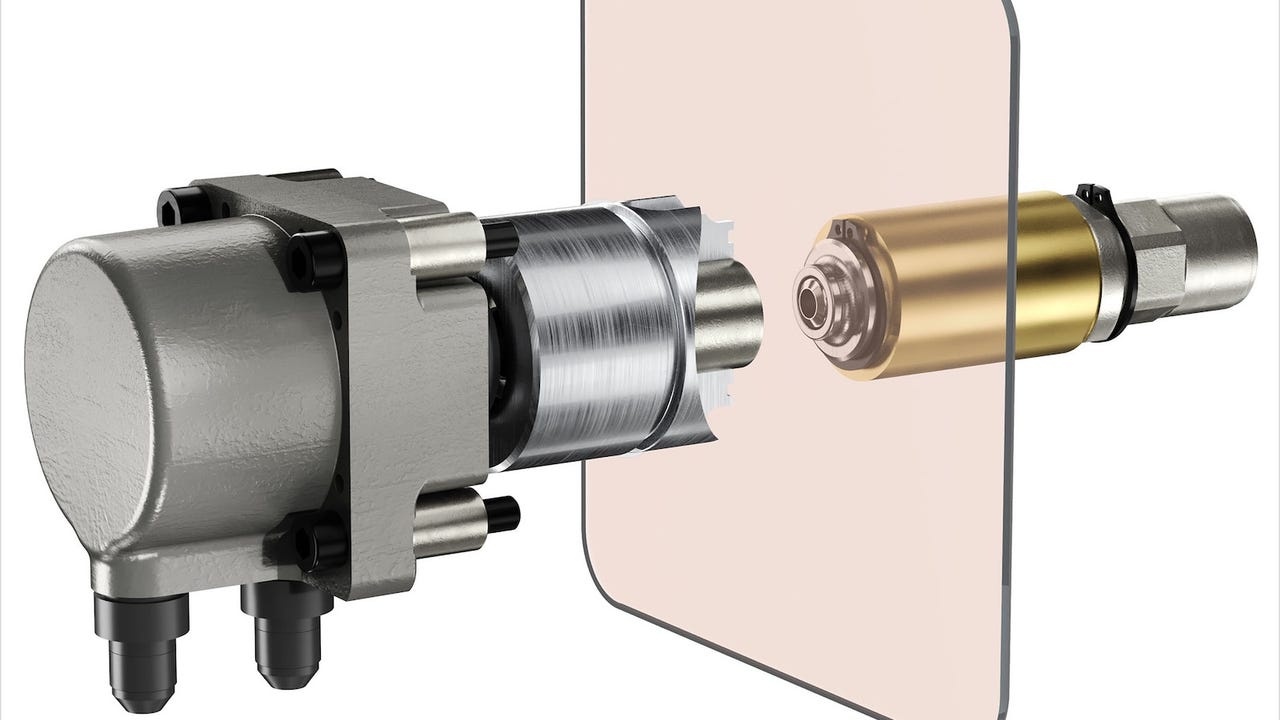

The Z.Sonic turn is equipped with an advanced indexing system that shifts part of the residual cooling away from the mold and makes part removal cycle-neutral, explained Zahoransky. While the mold is closed, an integrated rotary unit takes over the positioning for removal. At the same time, the next shot has already begun.

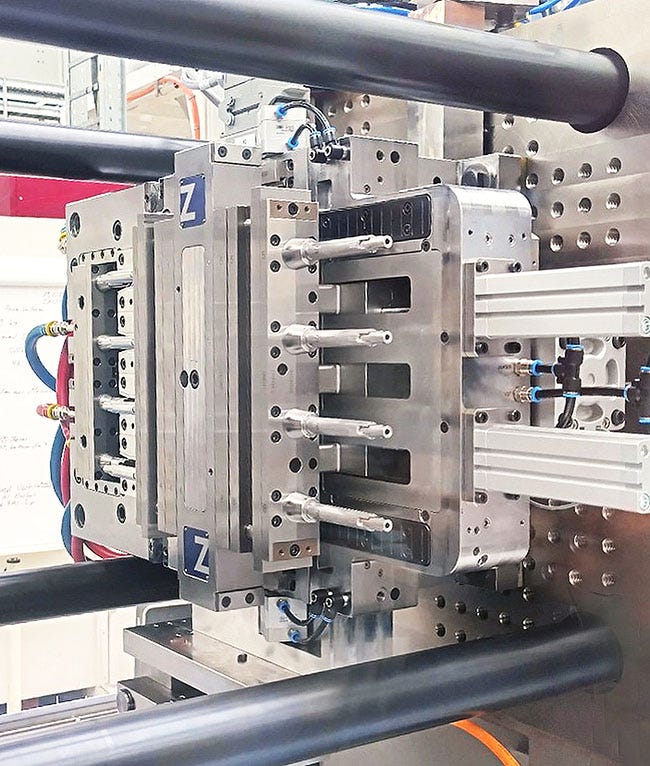

The Z.Sonic turn mold concept from Zahoransky accelerates the large-scale production of housings for insulin pens and auto-injectors in an energy- and space-efficient design. Image courtesy of Zahoransky.

A four-cavity mold for autoinjector housing was used in the application shown at K 2025, achieving a cycle time of around 12 seconds. The compact design reduces mold mass by around 1,000 kilograms compared with conventional systems. This shortens heating times, reduces energy consumption, and simplifies the design, as complex relative movements are no longer necessary, said Zahoransky.

Key benefits of the Z.Sonic turn include:

Increased annual output from approximately 8.5 to 12.8 million parts;

a 23% decrease in unit costs;

a compact design that takes up less space and consumes less energy;

despite a higher price point than conventional systems, the payback period is around nine months.

The Z.Sonic turn delivers a future-proof, scalable solution for manufacturers of pen and auto-injectors who want to quickly expand their capacities while increasing overall equipment effectiveness, according to Zahoransky. “Our approach is to focus on smart technologies rather than on more and more cavities. With Z.Sonic turn, we are demonstrating what Zahoransky stands for— innovation in action, consistently geared toward performance and quality,” said Head of Global Account Development Simon Hug.

120-plus years of manufacturing expertise

A family-owned company based in Todtnau-Geschwend, Germany, Zahoransky has been involved in machine engineering and mold making for more than 120 years. A full-service provider and technology partner for companies in the brush industry, medical technology and other sectors, Zahoransky provides customers with complete solutions for the manufacture of complex plastic, hybrid, and glass replacement products. The company develops and manufactures injection molds, upstream and downstream automation solutions, and quality control systems, and integrates injection molding machines and other system components for turnkey, fully automated production lines. Zahoransky operates sites in Germany, Spain, China, India, Japan, Brazil, and the United States.