On the heels of its world debut at K 2025 in Germany in October, Arburg is bringing its new electric injection molding machine concept stateside for the first time to MD&M West in February.

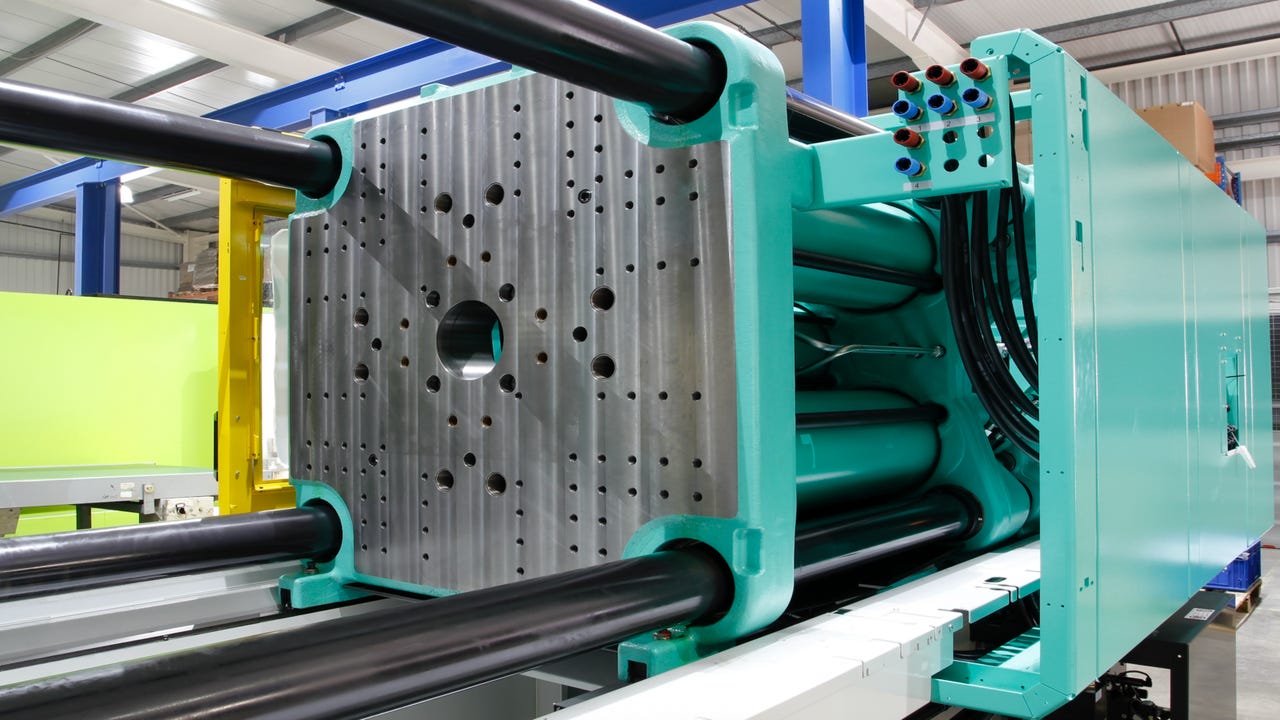

Arburg’s unveiling of the Trend electric presses at K was hailed as a “smashing success” by the German molding machine maker. At the event in Anaheim, it will display an Allrounder 1000 e Trend equipped with the new, user-friendly Gestica lite control system. The new machine line provides uncompromising performance and reliability and easy maintainance, according to Arburg, which also promises short delivery lead times.

MD&M West is a comprehensive manufacturing-focused trade show and conference for the medical technology, plastics, packaging, and automation sectors. It runs from Feb. 3 to 5, 2026, at the Anaheim Convention Center.

Setting a new injection molding standard

The Allrounder Trend sets a new benchmark in injection molding, according to Arburg Inc. President and CEO Martin Baumann. The machines are "easy to set up, operate and maintain — without compromising in any way on quality, precision, and reliability. They also impress with their low energy consumption and low investment and operating costs,” said Baumann.

An additional selling point, given the difficulty manufacturers encounter hiring and retaining skilled workers, is the intuitive Gestica lite control system, which enables relatively inexperienced personnel to operate the Allrounder Trend machines with ease, said Arburg. Additional support can be provided by optional smart assistants.

Integrated automation

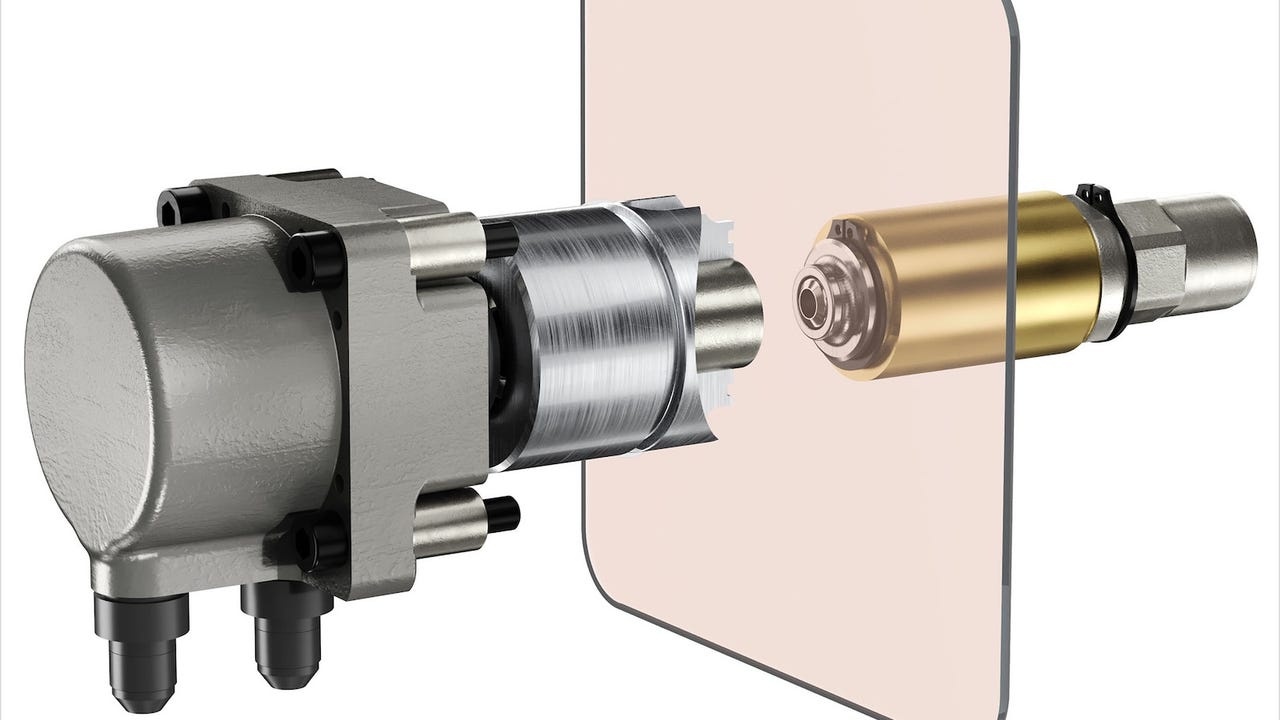

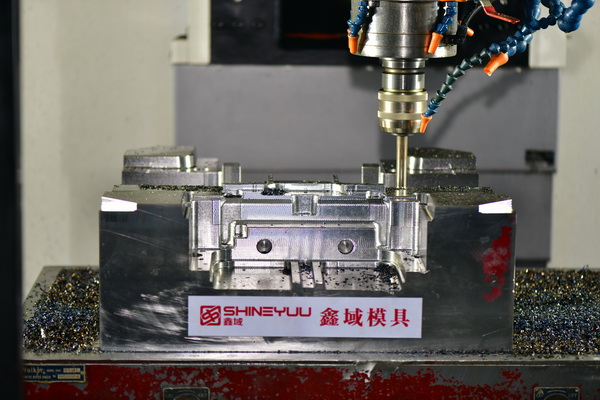

At stand 4611, Arburg’s Allrounder 1000 e Trend will produce a technical part using an eight-cavity hot runner mold from Adler Industrial Solutions Inc. The parts will be removed by a Multilift robotic system, which is fully integrated into the control unit, and fed into a storage system developed by Arburg, separated by cavity size.

Integrated automation systems in injection molding cells is a trend that Arburg has been following and in which it is fully invested. “Specifically, customers are pushing for greater networking between injection molding machines and peripherals for productivity reasons,” said Arburg. “Accordingly, there is a growing search for solutions to partially or fully automate and digitize production, as well as to offer greater transparency in production processes in terms of quality, service, and support. At Arburg, we can offer them all of this from a single source,” stressed Baumann.

Digitization on show

In addition to its new Trend portfolio of electric injection molding machines, Arburg will exhibit its digital products, including the arburgXworld customer portal and the company’s ALS manufacturing execution system. The capabilities of these digital products will be showcased as they process service and real-time production data from the Allrounder 1000 e Trend running at the Arburg stand.